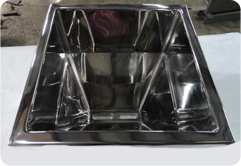

HOPPER CONE FUNNEL

Price 100000 INR/ Piece

HOPPER CONE FUNNEL Specification

- Material

- Stainless Steel, Mild Steel, as required

- Coating Material

- Optional Powder Coating or None

- Protection Level

- Corrosion Resistant (if made from stainless steel)

- Usage & Applications

- Bulk Material Handling, Chemical, Food Processing, Agriculture, Industrial Storage

- Surface Finish

- Polished or Matte Finish

- Size

- Varies as per requirement, typically diameter ranges from 300 mm to 1200 mm

- Fabrication Service Type

- Custom Metal Fabrication

- Fabrication Product

- Hopper Cone Funnel

- Fabrication Process

- Welded and Assembled

- Applicable Standards

- As per IS/ASTM norms

- Mounting Provision

- Legs or Flange Mount

- Capacity

- Customizable, from 10 liters to several cubic meters

- Wall Thickness

- Usually 2 mm to 5 mm depending on capacity and application

- Cleaning Access

- Available with removable covers or clean-out ports

- Color

- Natural metal, Powder-coated on request

- Top Design

- Open or Flanged

- Discharge Opening

- Circular, size customizable

- Welding Type

- TIG/MIG Welding

- Temperature Resistance

- Up to 300°C (depends on material selection)

- Shape

- Conical

HOPPER CONE FUNNEL Trade Information

- Minimum Order Quantity

- 1 Piece

- Main Domestic Market

- South India, North India, Mizoram, Daman and Diu, All India, Central India, Bihar, West India, East India, Gujarat, Arunachal Pradesh, Haryana, Tamil Nadu, Telangana, Karnataka, Kerala, Lakshadweep, Odisha, Meghalaya, Manipur, Andhra Pradesh, Chandigarh, Goa, Jharkhand, Assam, Punjab, Dadra and Nagar Haveli, Himachal Pradesh, Delhi, Andaman and Nicobar Islands, Chhattisgarh, Jammu and Kashmir, Madhya Pradesh, Maharashtra, Nagaland, Sikkim, Tripura, Pondicherry, Uttar Pradesh, Uttarakhand, West Bengal, , Rajasthan

About HOPPER CONE FUNNEL

Hopper Cone Funnel

Overview:A Hopper Cone Funnel is designed to streamline the flow of materials from a large container or storage unit into smaller vessels, conveyors, or machines. The funnel shape, typically with a cone-like bottom, aids in directing materials smoothly while minimizing blockages or spills. It's commonly used in industries like agriculture, food processing, pharmaceuticals, chemicals, and manufacturing.

Key Features:

-

Shape & Design: The funnel's conical or hopper-like shape allows for efficient gravity-fed discharge, ensuring that materials flow out smoothly without obstruction. The design prevents material clogging at the discharge point.

-

Material Construction: Made from durable, high-quality materials like stainless steel, plastic, or aluminum, the funnel is resistant to corrosion and wear, ensuring longevity in both harsh environments and food-grade settings.

-

Versatility: Suitable for a wide range of substances, including powders, grains, liquids, and even solid objects. It is available in multiple sizes to accommodate different container types and material flows.

-

Easy Handling: Typically equipped with features like a handle or base for secure placement and transport, making it user-friendly and easy to maneuver.

-

Applications: Used for filling containers, dispensing ingredients, or as part of a larger automated system where precise material transfer is essential. It is often used in processes such as packaging, production, and material processing.

-

Customization: Some models offer customizations, such as adjustable flow rates, different outlet sizes, and optional covers to prevent contamination or spillage.

Advantages:

- Increased Efficiency: The cone shape minimizes waste and ensures a quick and steady flow of materials.

- Enhanced Safety: It helps avoid spillage and accidents that may occur due to overflows or misdirected material flow.

- Easy to Clean: Smooth internal surfaces allow for quick cleaning, crucial for industries that require hygiene, like food processing or pharmaceuticals.

Applications:

- Food Processing: Used to funnel grains, flour, sugar, or other dry ingredients into mixers or packaging lines.

- Chemical Industry: Assists in transferring powders or granular substances to tanks or conveyors.

- Agriculture: Ideal for transferring seeds, fertilizers, or grains in bulk handling operations.

- Pharmaceuticals: For precise dispensing of active ingredients into production lines.

Flexible Customization for Diverse Applications

Our Hopper Cone Funnels can be tailored to accommodate capacities from 10 liters to several cubic meters, with wall thickness and diameters adjustable as per your operational requirements. Whether used in food processing, chemical industries, agriculture, or industrial storage, each unit is meticulously fabricated to meet specific needs, ensuring reliability and seamless integration into your process flow.

Robust Construction & Quality Assurance

Constructed from stainless steel or mild steel and welded using advanced TIG or MIG processes, our Hopper Cone Funnels provide superior strength and long-term durability. They are engineered to function efficiently under temperature extremes up to 300C, with optional powder-coating and corrosion-resistant finishes to withstand harsh industrial environments.

FAQ's of HOPPER CONE FUNNEL:

Q: How is the hopper cone funnel customized to suit different applications?

A: Each hopper cone funnel is made to order, allowing you to specify capacity (from 10 liters up to several cubic meters), discharge opening size, wall thickness, mounting provision, top design, and even material. This flexibility ensures optimal fit and performance whether deployed in agriculture, food processing, chemicals, or storage industries.Q: What materials are used in manufacturing the hopper cone funnel, and what are the benefits?

A: We fabricate hopper cone funnels from high-grade stainless steel or mild steel, as per your specifications. Stainless steel provides excellent corrosion resistance, making it ideal for food and chemical applications, while mild steel offers robust structural strength at a cost-effective price. Both options can be finished with powder coating or left with a polished/matte metal finish.Q: When should I opt for a flanged top or powder coating on my hopper funnel?

A: A flanged top is advisable for applications requiring a secure seal with adjoining equipment or bulk material systems. Powder coating is recommended when additional protection against corrosion, aesthetics, or environmental exposure is necessary, particularly for outdoor or chemically challenging environments.Q: Where can cleaning access be added to the hopper cone funnel, and how does it help?

A: Cleaning access is typically integrated via removable covers or clean-out ports, strategically positioned on the hopper for easy reach. This design feature simplifies maintenance, supports hygiene (critical in food and chemical sectors), and minimizes operational downtime.Q: What is the standard fabrication process for your hopper cone funnels?

A: Fabrication involves precise metal cutting, forming, and assembly using TIG or MIG welding methods. After initial assembly, the units are thoroughly inspected and finished according to client specifications, which may include polishing, matte finishing, or applying protective coatings. All steps conform to relevant IS/ASTM standards for safety and quality.Q: How does the hopper cone funnel support bulk material handling operations?

A: Its conical shape ensures efficient, obstruction-free discharge of bulk solids or liquids. The customizable discharge opening, mounting options, and robust build make it suitable for reliably transferring, storing, or metering materials across industrial, agricultural, and processing installations.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Fabricators Category

Sheet Metal Fabricators

Price 180 INR / Piece

Minimum Order Quantity : 1 Piece

Material : Carbide, High Speed Steel, Tungsten Cobalt Alloy

SHEET METAL FABRICATION

Price 1000 INR / Piece

Minimum Order Quantity : 1 Piece

Fabrication Service Type : Custom Metal Fabrication

Fabrication Product : Sheet Metal Fabrication

Fabrication Process : Laser Cutting, Bending, Punching, Welding

Material : Mild Steel, Stainless Steel, Aluminium

WINDOW GRIL

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Fabrication Service Type : Custom Metal Fabrication

Fabrication Product : Window Gril

Fabrication Process : Cutting, Welding, Finishing

Material : Mild Steel/Iron

Stainless Steel Fabrication

Price 2150.00 INR / Piece

Minimum Order Quantity : 1 Piece

Fabrication Service Type : Ni

Fabrication Product : Steel Fabrication

Fabrication Process : Ni

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free