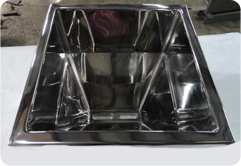

PVD COTTING WITH FABRICATION WORKS

Price 2000 INR/ Piece

PVD COTTING WITH FABRICATION WORKS Specification

- Coating Material

- Titanium Nitride (TiN) via Physical Vapor Deposition (PVD)

- Material

- Stainless Steel (Grade 304/316 available)

- Protection Level

- High Corrosion and Wear Resistance

- Size

- Customizable as per client requirements

- Usage & Applications

- Architectural Elements, Decorative Panels, Railings, Elevators, Commercial Interiors

- Surface Finish

- Mirror Gloss / Satin Gold Finish

- Fabrication Service Type

- Custom Fabrication and PVD Surface Treatment

- Fabrication Product

- PVD Coated Metal Structure

- Fabrication Process

- Precision Sheet Metal Fabrication with PVD Coating

- Thickness Range

- 0.8 mm to 3.0 mm

- Coating Thickness

- 0.2 0.5 microns

- Technology

- PVD (Physical Vapor Deposition) Vacuum Coating

- Durability

- Outdoor and Indoor Use, Long-lasting Finish

- Lead Time

- 2-4 Weeks Depending on Project

- Hardness

- Up to 2500 HV (Vickers Hardness)

- Environmental Compliance

- Eco-friendly, No Hazardous Chemicals Used

- Maintenance

- Easy to Clean, Fingerprint Resistant

- Edge Finish

- Seamless, Burr-free Edges

- Color Options

- Gold, Rose Gold, Black, Bronze, Champagne, Customized Shades

- Installation

- On-site Installation Service Available

- Adhesion Strength

- Strong Molecular Bonding

PVD COTTING WITH FABRICATION WORKS Trade Information

- Minimum Order Quantity

- 5 Pieces

- Main Domestic Market

- Lakshadweep, Mizoram, Pondicherry, North India, Karnataka, Central India, West India, Gujarat, Kerala, East India, Jharkhand, Odisha, Punjab, Meghalaya, Manipur, Andhra Pradesh, Bihar, Chandigarh, Daman and Diu, Goa, Assam, Delhi, Dadra and Nagar Haveli, Andaman and Nicobar Islands, Arunachal Pradesh, Madhya Pradesh, Haryana, Himachal Pradesh, Jammu and Kashmir, Maharashtra, Nagaland, Tripura, Rajasthan, Sikkim, Tamil Nadu, Uttarakhand, Uttar Pradesh, West Bengal, , All India, South India, Chhattisgarh, Telangana

About PVD COTTING WITH FABRICATION WORKS

PVD Coating with Fabrication Works combines the highperformance Physical Vapor Deposition PVD coating technology with traditional fabrication processes to create customized products with superior surface finishes enhanced durability and aesthetic appeal This combination of coating and fabrication techniques is used for a variety of industries including architecture automotive electronics medical devices and more

PVD Coating with Fabrication Works Products Description

OverviewPVD Physical Vapor Deposition is a vacuum coating process that involves vaporizing a material usually metal in a vacuum chamber which then condenses on the surface of the fabricated product to create a thin durable and corrosionresistant coating When combined with fabrication works PVD coating is applied to a range of metal plastic and other substrates to create products that are not only strong and durable but also aesthetically pleasing

Key Features

HighQuality Finish The PVD coating creates a smooth uniform and durable surface on the product providing it with a glossy or matte finish The finish can be customized to meet the aesthetic preferences of the customer available in various colors and textures such as gold chrome black titanium and more

Enhanced Durability PVD coating significantly enhances the wear resistance hardness and corrosion resistance of the fabricated products This makes the products more suitable for highwear applications reducing the likelihood of surface damage scratches and oxidation over time

Aesthetic Appeal PVD coating adds a layer of color sheen and texture to products which is particularly beneficial for decorative elements in interior design jewelry automotive parts and more The coating improves the visual appeal and can be tailored to specific color schemes or design themes

Environmentally Friendly PVD is an environmentally safe and nontoxic process compared to traditional coating methods It doesnt involve harmful chemicals or solvents making it a safer option for both workers and the environment

Customizability Fabricated products can be made to order in various sizes and configurations with the option to apply PVD coatings in different finishes colors and thicknesses This makes the process highly adaptable for both functional and decorative applications

Corrosion and Scratch Resistance The PVD coating forms a protective layer that offers high resistance to rust scratches and other forms of surface degradation which makes the coated products ideal for hightraffic areas or harsh environments

Fabrication ProcessFabrication works typically involve the cutting bending welding and assembling of raw materials such as metal sheets bars or tubes into the desired form Once the fabrication is complete the products undergo the PVD coating process to add the finishing touch The combination of these processes allows for a high level of customization precision and durability in the final product

Common Materials Used in Fabrication and PVD Coating

Stainless Steel Known for its corrosion resistance stainless steel is commonly used for highend applications including architectural elements hardware and automotive parts

Aluminum Lightweight and corrosionresistant aluminum is often used in automotive and aerospace applications as well as in decorative items

Brass A popular material for decorative items brass benefits from PVD coatings that enhance its color and appearance

Copper Copper is frequently used for its aesthetic appeal in decorative products such as lighting fixtures and PVD coating enhances its durability and resistance to tarnishing

Titanium Known for its strength and lightweight properties titanium is frequently used in highperformance industries such as aerospace and medical devices

Plastics and Polymers Some plastic components can also be coated with PVD to improve their scratch resistance and appearance providing a metallic finish without adding much weight

Advantages

Improved Surface Hardness PVDcoated products have a much higher surface hardness which provides better protection against wear scratches and damage

Longer Lifespan The combination of fabrication and PVD coating increases the products lifespan by protecting it from corrosion oxidation and wear reducing the need for frequent repairs or replacements

Enhanced Aesthetic Quality PVD coatings can provide vibrant and highquality finishes adding a luxury look to products used in architecture interior design and automotive industries

Uniform Coating PVD coatings are applied uniformly ensuring consistency in color and texture across the product which is especially important in largescale production runs

NonToxic and Safe Since PVD coatings do not involve harmful chemicals or toxic solvents they are safer for both workers and consumers compared to traditional coating methods like electroplating

Applications

Architecture Interior Design

PVDcoated metal panels trims and decorative elements enhance the aesthetic appeal of interiors Products such as door handles railings light fixtures and curtain rods can be fabricated from stainless steel or aluminum and coated with gold bronze or black finishes for a premium look

Automotive Industry

PVD coating is widely used in automotive parts such as wheels bumpers exhaust tips and grilles to improve both the durability and the appearance of parts exposed to harsh conditions

Custom PVD coatings like chrome or gold finishes are popular for enhancing the visual appeal of vehicle exteriors

Jewelry

Jewelry components including rings bracelets and necklaces are fabricated from base metals like brass or stainless steel and coated with PVD to give them a shiny precious metallike finish

PVD coatings on jewelry offer durability and an attractive appearance without the cost of precious metals like gold or platinum

Aerospace

Aircraft components and parts including fasteners panels and fittings are fabricated and coated with PVD to improve their resistance to corrosion and wear especially in harsh environmental conditions like high temperatures and humidity

Consumer Electronics

Components like mobile phone cases laptop covers and other electronic enclosures are fabricated from aluminum or plastic and coated with PVD to enhance their scratch resistance and aesthetic appeal

Medical Devices

Medical instruments implants and devices are often fabricated from stainless steel or titanium and then coated with PVD to improve their durability corrosion resistance and biocompatibility for use in medical environments

Furniture and Fixtures

Custom furniture pieces like tables chairs and cabinets as well as fixtures such as handles knobs and faucets are often fabricated from metal and coated with PVD to achieve a premium finish thats both durable and visually appealing

Product Variations

PVDCoated Furniture Custom metal furniture with decorative PVD finishes such as gold chrome or black

PVDCoated Automotive Parts Wheels bumpers and grille accents that feature a highperformance PVD coating for durability and style

Decorative Interior Elements Door hardware light fixtures and trim elements in PVDcoated finishes to add luxury and resistance to wear

PVDCoated Jewelry Rings necklaces and bracelets with PVD coatings that give them a highend look while ensuring longevity

PVDCoated Medical and Aerospace Components Titanium and stainless steel parts with coatings that ensure corrosion resistance and increased lifespan in critical environments

Advanced PVD Coating Technology

Our fabrication works utilize state-of-the-art Physical Vapor Deposition (PVD) vacuum coating, resulting in a titanium nitride layer that ensures superior hardness, vibrant colors, and exceptional longevity. The process is environment-friendly and uses no hazardous chemicals, making it ideal for modern sustainable projects.

Custom Fabrication for Varied Applications

We provide custom fabricated metal structures with PVD surface treatment, precisely manufactured to meet client specifications. From sheet thickness (0.8 mm-3.0 mm) to finishing and color, our products are tailored for each order, ensuring perfect fit for railings, panels, elevators, and other architectural elements.

Durability and Low Maintenance

Our PVD coated products feature a long-lasting finish, excellent edge work, and resistance to fingerprints, corrosion, and scratches. Designed for both indoor and outdoor settings, the durable surfaces are easy to clean and require minimal maintenance, promising years of reliable performance.

FAQ's of PVD COTTING WITH FABRICATION WORKS:

Q: How is the PVD coating process applied during fabrication?

A: The PVD (Physical Vapor Deposition) coating is applied in a vacuum chamber where titanium nitride is deposited onto stainless steel surfaces during or after precise sheet metal fabrication. This creates a strong molecular bond for durable and vibrant finishes.Q: What applications are suitable for PVD coated fabricated metal structures?

A: These structures are ideal for architectural elements like railings, decorative wall panels, elevator interiors, commercial spaces, and bespoke interior design projects, thanks to their customizable colors, high durability, and superior finish.Q: When can I expect delivery of my custom PVD fabrication order?

A: Lead times generally range from 2 to 4 weeks, depending on the complexity and size of your project. Our team coordinates closely throughout the process to meet your specific timelines.Q: Where is the PVD coating and fabrication service available?

A: We operate as an exporter, fabricator, manufacturer, and service provider in India, serving both domestic and international clients. On-site installation services are also offered for seamless integration.Q: What are the maintenance requirements for PVD coated metal products?

A: Maintenance is straightforward-simply wipe surfaces with a soft cloth and mild cleaner. The PVD finish is fingerprint-resistant, avoiding smudges and keeping the shine intact with minimal effort.Q: What are the benefits of choosing a PVD coated finish over traditional painting or plating?

A: PVD coatings offer stronger adhesion, superior hardness (up to 2500 HV), and better resistance to corrosion and wear compared to traditional finishes. The result is a longer-lasting, eco-friendly, and more vibrant surface.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Stainless Steel Fabricators Category

Housing Single Row Drawer

Price 6510 INR / Piece

Minimum Order Quantity : 1 Piece

Fabrication Process : Ni

Fabrication Service Type : Ni

Fabrication Product : Row Drawer

WINDOW GRIL

Price 2000 INR / Piece

Minimum Order Quantity : 1 Piece

Fabrication Process : Cutting, Welding, Finishing

Fabrication Service Type : Custom Metal Fabrication

Fabrication Product : Window Gril

SS Powder Funnel

Price 30 INR / Piece

Minimum Order Quantity : 1 Piece

Fabrication Process : Ni

Fabrication Service Type : Ni

Fabrication Product : Powder Funnel

Stainless Steel Fabrication

Price 2150.00 INR / Piece

Minimum Order Quantity : 1 Piece

Fabrication Process : Ni

Fabrication Service Type : Ni

Fabrication Product : Steel Fabrication

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS