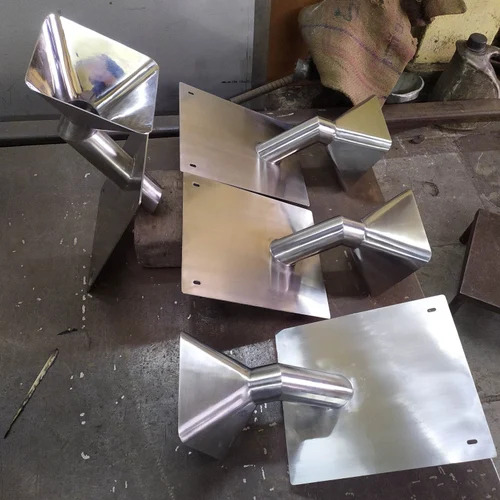

SS Pipe Fabrication

Price 2150 INR/ Piece

MOQ : 1 Piece

SS Pipe Fabrication Trade Information

- Minimum Order Quantity

- 1 Piece

- Payment Terms

- Letter of Credit (L/C), Letter of Credit at Sight (Sight L/C), Delivery Point (DP), Cash in Advance (CID), Cheque, Cash Advance (CA)

- Supply Ability

- 100 Pieces Per Day

- Delivery Time

- 10-15 Days

- Main Export Market(s)

- Australia, South America, Eastern Europe, Middle East, Western Europe, Asia, Central America

- Main Domestic Market

- All India

About SS Pipe Fabrication

SS Pipe Fabrication is made available by us that is the process of creating predesigned stainless steel pipes for a variety of uses. Stainless steel fabricated pipe can be used in a variety of fields from plumbing. The pipe fabrication is the process of welding piping components such as pipes, elbows, tees, flanges, etc., into engineered piping systems. SS Pipe Fabrication can be defined as the process of cutting, bevelling, and welding piping components such as pipes, tees, elbows, flanges, reducers, etc.

Precision-Engineered Solutions

Our SS Pipe Fabrication services are tailored to ensure every piece meets strict engineering standards. With advanced TIG/MIG welding techniques and polished finishes, each pipe is crafted for exceptional durability and accuracy, making them ideal for a variety of demanding applications.

Verified Quality and Corrosion Resistance

Every stainless steel pipe undergoes comprehensive inspection, ensuring 100% quality assurance. Our fabrication processes prioritize corrosion resistance to extend product lifespan, making these pipes dependable for industrial, construction, and plumbing environments.

Custom Fabrication to Client Specifications

We provide fully customizable SS pipe fabrication services. Whether you require specific end typesplain, beveled, or threadedor adherence to ASTM, ASME, or DIN standards, our team delivers solutions designed specifically around your project needs, offering flexibility and precision.

FAQs of SS Pipe Fabrication:

Q: How is corrosion resistance ensured in your SS pipe fabrication?

A: We select high-grade stainless steel and utilize advanced welding techniques to deliver pipes with excellent corrosion resistance. Each pipe is also 100% quality checked to guarantee long-term durability in harsh environments.Q: What customization options are available for SS pipe fabrication?

A: We offer complete customization based on client requirements, including choice of pipe ends (plain, beveled, or threaded), various finishes, and compliance with ASTM, ASME, or DIN standards. Our services support projects of different scopes and specifications.Q: When should I opt for TIG or MIG welding for my pipe project?

A: The choice between TIG and MIG welding depends on the specific requirements of your application. TIG welding is preferred for precise, clean welds, especially in high-quality or aesthetic projects. MIG welding is ideal for quicker production needs and thicker materials.Q: Where can SS pipe fabrication be used effectively?

A: Our fabricated stainless steel pipes are suitable for industrial facilities, construction sites, plumbing systems, and diverse fabrication works where strength, corrosion resistance, and reliable performance are critical factors.Q: What is the process for placing a custom fabrication order?

A: To place a custom order, clients simply share their project specifications, including length, end type, welding preference, and applicable standards. Our team collaborates closely with you from design to delivery to ensure all requirements are met.Q: How do clients benefit from choosing your SS pipe fabrication services?

A: Clients receive precisely engineered pipes backed by robust quality control, superior corrosion resistance, and flexible customization options. Our comprehensive support and expertise ensure your project is completed efficiently and meets all necessary standards.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry

Send Inquiry

Send Inquiry Send SMS

Send SMS Call Me Free

Call Me Free